ONLINE Dan Fulleton Farm Equipment Retirement Auction

THIS WILL BE AN ONLINE AUCTION Visit bakerauction.com for full sale list and information Auction Soft Close: Mon., March 3rd, 2025 @ 12:00pm MT Location: 3550 Fulleton Rd. Vale, OR […]

Published 7:00 am Thursday, June 24, 2021

POULSBO, Wash. — Around 7 a.m. in the Central Market grocery store on the Friday before Memorial Day, a shopper pulled a bunch of spinach from a shelf, stuffed it in a bag and dropped it into her cart.

The sequence took seconds. But the story behind this bunch of spinach and how it got there is far from simple.

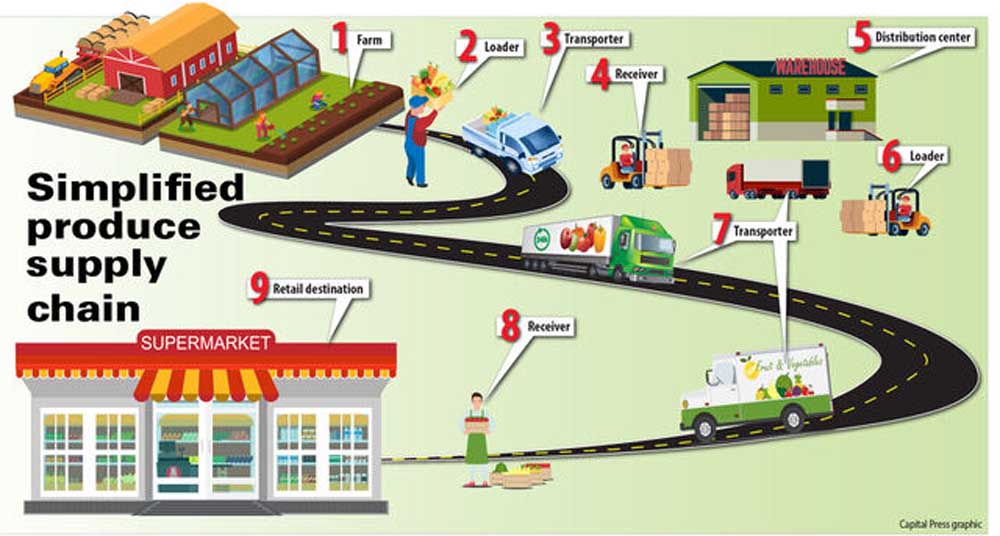

The produce supply chain is an ensemble of parts and people working in concert to bring food to consumers’ tables. The size of the 2021 U.S. fruit and vegetable market, measured by revenue, is $5.3 billion, according to market research firm IBISWorld. To take a snapshot of this system, the Capital Press followed a precise bunch of spinach from the farm where it was grown to the retail store.

Following a lowly spinach bunch, in Lot No. 8525, opened a window into this complex system.

Dharma Ridge Organic Farm

Quilcene, Wash.

8 a.m.

The spinach trail began in Quilcene, Wash., on the Olympic Peninsula. Here lies Dharma Ridge Organic Farm, a strip of land hemmed in by evergreen trees.

Zach Wailand and his wife, Haley Olson-Wailand, started this farm in 2003. They began by selling to farmers markets.

Around 2012, they started selling to Central Market, one of six stores in a regional grocery chain, Town & Country Markets Inc.

As the farm grew, the couple wanted to sell to more stores. But delivering the produce seemed daunting.

That’s when Joe Pulicicchio, director of produce and floral at Town & Country Markets, introduced the farmers to Pacific Coast Fruit Co., a regional distributor based in Portland, Ore., with a second warehouse in Kent, Wash., near Seattle.

“We didn’t want to be in the trucking business, so it made sense,” said Wailand.

Scroll ahead five years. On May 27, 2021, the crew at the Wailands’ farm harvested a field block of spinach, packaged it in boxes with tracking numbers and stored it.

Even before harvest, the Dharma Ridge farmers had invested time and money in this crop.

Wailand estimates that for a single, 24-count box of spinach, the farm spent $2.26 on the box; $8 on labor, 40 cents on fertilizer, crop protection and seed; 10 cents each on fuel and early-season irrigation; and a few dollars, perhaps $3, on overhead including leases, equipment payments, utilities, insurance and certifications. This adds up to $13.86 spent per box, or 58 cents per bunch.

Dharma Ridge Organic Farm

Quilcene, Wash.

6:15 a.m.

“Let’s load ‘er up.”

The voice belonged to Martin Rowland, a Pacific Coast truck driver.

Wailand, the farmer, used his forklift to hoist a pallet, Lot No. 8525, into the semi-truck.

Historically, it’s been common in many states to separate the roles of grower, loader, shipper, receiver, distributor and retailer, with each role assigned to a different company or contractor.

But recently, especially in the Pacific Northwest, supply chains have become increasingly consolidated. Now, a farmer might grow, harvest, package and deliver to a distributor. Or, a retailer might own a distribution center and coordinate loading, transport and offloading. Additionally, organic and conventional supply chains — once separate — are merging.

The scene at Dharma Ridge reflected this. Wailand loaded the spinach; Pacific Coast handled the rest.

The morning air was cold and damp, but Rowland, the driver, stood in shorts and a T-shirt, his tattooed arms and legs exposed. He had been making deliveries to retailers through the night and was returning to Pacific Coast’s warehouse in Kent. This backhaul was his final stop.

Pacific Coast managers say they’re lucky to have Rowland when the truck driver shortage has reached a “crisis level” and freight rates are double or triple the usual cost.

“The driver shortage is getting acute,” said David Nemarnik, CEO of Pacific Coast.

Many companies have raised wages as an incentive, sometimes entering into bidding wars for drivers. These trucking expenses are passed on to consumers.

On the road

6:30 a.m.

Produce loaded, the truck began its two-hour journey.

Rowland drove through battering rain — past hillsides freckled with daisies and mustard-yellow Scotch broom, over the Hood Canal Floating Bridge, toward Seattle’s heart.

This is Rowland’s favorite part of his job: “the beautiful Washington drives.”

Pacific Coast Fruit Co.

Kent, Wash.

9 a.m.

The truck arrived at a receiving dock at Pacific Coast’s 85,000-square-foot facility.

Inside, the warehouse buzzed with activity: specialists grading apricots, employees zipping by on forklifts, produce buyers in reflective vests calling out instructions.

An employee unloaded the pallet of spinach the Capital Press was following, dropping it in a spacious room kept at 34 degrees Fahrenheit — penetrating, finger-numbing cold.

Within minutes, employees had unraveled plastic wrap, documented lot numbers and slapped stickers on the load signifying which slot in the warehouse the produce was destined for.

It was grading time.

Jerry Vanisko, quality assurance manager, opened a software application on his tablet to help him generate a grade, or quality level, for the spinach.

To randomize sampling, Vanisko pulled one box from the stack’s top, one from the middle and one from the bottom.

He opened the first box, letting its content spill out onto a counter: perky bunches of spinach with vibrant, spoon-shaped leaves.

“Beautiful. Would you look at that? Just beautiful,” he said. The corners of his eyes crinkled.

He weighed the spinach, checked its temperature, then followed software prompts, answering questions about any discoloration, yellowing, limpness, mold or decay. The spinach got a top grade.

He then photographed the spinach: images that could be retrieved later in case of complaints.

Vanisko walks a tightrope every day as he grades. If he’s too strict, he could hurt farmers by throwing out too much product. If he’s too lax, he could upset retailers and consumers.

“When I first started working here, I looked at everything through the produce manager’s eye. I was much pickier,” said Vanisko, who used to work as a retail produce buyer and has been in the industry more than 40 years. “Now, I’ve got multiple customers to please.”

Tom Brugato, Pacific Coast’s president, said the company tries to hire people with industry experience.

“I think our claim to fame has been hiring the right people,” said Brugato.

But food employees in general are hard to find, he said. The labor shortage is a perennial, and intensifying, challenge across the entire food chain.

Pacific Coast’s leaders got into the industry through family. Nemarnik’s father started the company in 1977. Brugato married Nemarnik’s sister, bringing him into the fold.

“Did I choose it or did it choose me? I’m not sure,” said Brugato.

He laughed.

It was time for the pallet of spinach to move to its slot.

At Pacific Coast, produce is organized by atmosphere. Wet produce, such as lettuce, is stored in the “wet” room with a mist machine and the air temperature near freezing. Each room thereafter is warmer and drier, all the way to the “tropical” room, where fruits such as mangoes are stored. Each room carries its own smells of ripening produce.

Even after produce is settled at its “temporary address,” there’s work to be done, said Jenny Williams, a category produce buyer.

To her left, a man, surrounded by box-towers resembling a city skyline, was ripening bananas.

Everywhere, boxes were stacked on wooden pallets. Several recent events have led to lumber shortages, and in turn, to a 400% increase in pallet costs, according to the United Fresh Produce Association.

But, Williams said, Pacific Coast can’t ditch using pallets. USDA requires pallet use for food safety.

“We pay by the pallet, which translates into us passing on our costs,” said Williams.

By mid-morning, Williams, along with Joe Hanson, Washington division president, were gearing up for the deluge of retail orders expected around 2 p.m.

Williams can generally predict what retailers will order and meet their needs. But sometimes, there isn’t enough supply.

“It’s the constant struggle with Mother Nature,” said Williams. “You try to do the best you can, but you can’t beat her.”

When there’s more demand than supply, Williams sells a smaller portion to each retailer.

The company employs more than 450 people and buys from hundreds of farms across the West, but its leaders say they like to keep relationships personal.

“It still feels like a handshake business in many ways,” said Nemarnik, the CEO.

A call comes in, and a buyer writes a purchase order for a $90,000 load of avocados — no contract, based on trust.

In contrast, national distribution chains are more formalized.

A.G. Kawamura, a third-generation California grower who sells through GEM Pack Berries LLC to national chains including Walmart, Costco, Safeway and Kroger, said in the 1980s, most orders were contract-less, over the phone. Now, he said, most “program orders” are online.

Some workers thrive on logistics.

Williams, the category buyer, said she enjoys the adrenaline of planning. “I’m very OCD,” she said of her attention to detail.

The best feeling, she said, is seeing a “good rotation” — like when there are more orders for onions than cases available, but then an inbound truck drops off more onions in the nick of time.

“It feels good to see the produce go,” she said, “that moment when you think: ‘It’s on its way.’”

Pacific Coast Fruit Co.

Kent, Wash.

1 a.m.

Spinach Lot No. 8525 sat in the warehouse the remainder of the day.

The next morning, it moved again. This time, Pacific Coast delivered to Poulsbo, a tourist town on Liberty Bay along Puget Sound.

The spinach had traveled many hours and miles, yet this journey was highly localized compared to many supply chains across the U.S.

Central Market

Poulsbo, Wash.

3:30 a.m.

Inside Central Market, employees pulled apart boxes, documented the order and put the spinach in the organic section’s wet display case. The price tag: $3.98 per bunch.

There are many expenses behind the scenes beyond obvious ones like water and labor, said Joe Pulicicchio, director of produce and floral: the overhead for the building, cooler expenses, even cardboard, the cost of which is “off the chart.”

Pulicicchio said he’s passionate about helping farmers succeed. But as a retailer, he has to make everyone happy: grower, distributor and consumer. On the one hand, he can’t make a grower or distributor feel underpaid. On the other, he doesn’t want consumers to feel price-gouged.

“You have to please everyone,” he said.

But Pulicicchio said he enjoys the challenge. It’s a moving game. No two days are the same.

“One thing’s for sure: I’m never bored.”

After 6 a.m., customers trickled in.

At 6:45, Julie Wuesthoff, the produce manager, arrived for her 7 a.m. shift.

A former chef and food nonprofit leader, she’s worked at Central Market for 15 years.

Eighteen people work in this section: restocking, sweeping, straightening, organizing displays.

“It takes many hands to maintain this,” said Wuesthoff.

On the floor, she set to arranging displays.

Every detail of the display configuration matters, said Wuesthoff. Even a subtle change can impact sales. Everything is calculated and considered: color schemes, spacing between rows, angles, signage, “staple” items versus seasonal impulse buys.

“There’s an art to it,” she said.

Wuesthoff glanced sideways, where a woman was putting the bunch of spinach into her cart.

“Well, there you go,” she said. “There’s more to it than meets the eye.”

In this two-part series, the Capital Press follows food from farm to retail store. This week’s story follows fresh fruits and vegetables. Next week’s story will follow the separate supply chain for groceries and other value-added products.

Zach Wailand, Dharma Ridge Organic Farm:

David Nemarnik, Pacific Coast Fruit Co.:

Tom Brugato, Pacific Coast Fruit Co.:

Tim Kovis, Washington State Tree Fruit Association:

Kate Evans, Washington State University Extension Center:

Bob Mast, CMI Orchards:

John Henry Wells, Food Plus Technology LLC:

A farmer who did not wish to be named:

High-level manager at Albertsons who asked not to be named:

Mason Brady, Homegrown Organic Farms:

A.G. Kawamura, Orange County Produce LLC.: